Wholesale supply of custom Abnormal spring

The difference between a special-shaped spring and a conventional spring is that the spring itself is irregular, with bending and a large number of complicated angle designs. Suitable for some special occasions.

Description

There are many types of special-shaped springs, which are introduced as follows:

(1) Variable diameter spiral spring: It is used in some special occasions. The material of variable diameter spring is generally round cross-section material, and most of them bear compressive load.

(2) Leaf spring: The material of this spring is spring strip (or plate), which is processed by corresponding molds on special equipment or general pressure processing machine tools. The material thickness of leaf springs, wave springs, and light springs is relatively thin, while the material thickness of medium or large disc springs is often thicker. This type of spring has a wide range of uses.

(3) When the installation space is limited, springs of rectangular cross-section materials are often used, because springs made of rectangular cross-section materials can obtain a larger load in the same space and the same amount of deformation. Compared with the spring of round cross-section material, this kind of spring has a larger cross-sectional area in the same space, so it absorbs more energy. It can be used for heavy machinery, stamping dies or springs with extremely high stiffness.

(4) Disc springs are small in size and light in weight. They are widely used in buffering and vibration isolation, and are widely used in stamping dies, valve clutch fasteners, and petroleum and geological engineering machinery.

(5) The convex helical compression spring can get a larger amount of deformation because the coils with smaller ends can be embedded in the middle ring. For example, some convex type automobile brake springs are always in a tight state at ordinary times. When the automobile valve is opened, the spring restores its deformation and drives the brake to brake the automobile. The hair clipper also uses the characteristic of the convex spiral spring to obtain greater deformation and stress in an effective space.

(6) The scroll coil spring has a similar function to the conical coil spring. It absorbs a large amount of energy under pressure. Due to the difficulty of manufacturing, it is only used in special situations limited by space. The flat scroll spring has a large number of turns, a large deformation, and can store a large amount of energy. It is mostly used for compression springs and energy storage components in instruments.

(7) The leaf spring can be made of a single spring steel plate or multiple sheets, with good cushioning and damping performance, especially the strong damping performance of multi-leaf springs, which are mainly used for suspension devices of automobiles, tractors and railway vehicles.

(8) Unequal pitch coil springs are mainly used for suspension springs of motorcycles and small passenger cars and high-speed engine valve springs. On the same spring, it can not only meet the requirements of small stiffness when the deformation is small, but also meet the requirements of high stiffness when the deformation is large. The unequal-pitch spring can meet these special requirements.

(9) The torsion bar spring is actually a straight bar made of elastic material that is subjected to torque. It has a large deformation energy per unit volume and is mainly used for suspension devices of various vehicles.

(10) The ring spring is made up of an outer ring with an inner cone and an inner ring with an outer cone. The logarithm of the inner and outer rings is determined according to the size of the load and the requirements of deformation. Ring springs have high damping capacity and are mainly used for heavy equipment and buffer devices.

(11) Wire springs are various wire springs made of spring wire, generally made of cold drawn spring steel wire. Wire springs are mostly used where the load is small and the load characteristics are not strictly required. The cross section of the wire spring is often circular, so its load has no direction limit, and it has the same bending stiffness in all directions.

(12) There are two types of spring clamps: round cross-section materials and rectangular cross-section materials. Sometimes, for ease of assembly, the clamp ring is made into an end and then bent a section. When manufacturing the clamp ring, the tightly wound spring ring can be flattened by itself after being cut off, and it must have a relatively large initial stress during winding.

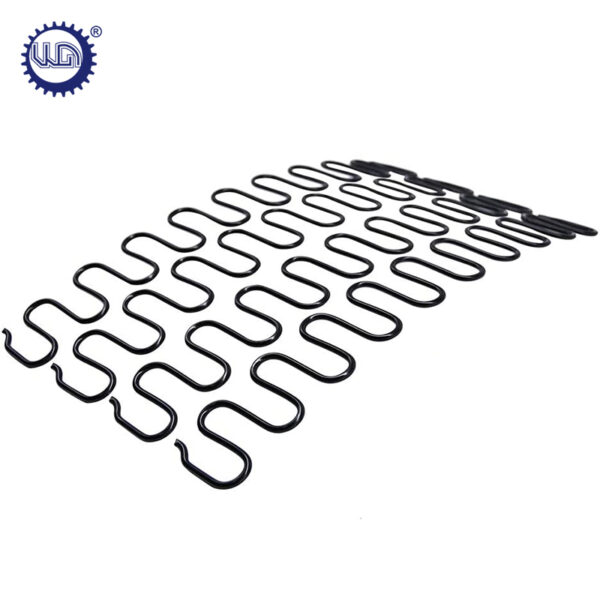

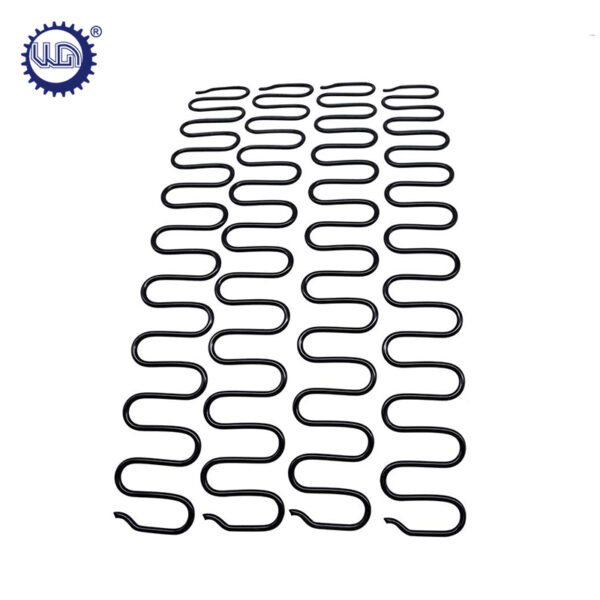

(13) The serpentine spring is named after its twisty shape like a snake. According to its shape, it is also called “Z” shape and “S” shape spring. It is widely used in car seat cushions, so it is also called a seat spring.

(14) Multi-strand spiral springs generally first twist 0.5mm~3mm steel wires into steel cables, and then coil them into springs. The most commonly used are 3~4 strands of steel cables without center strands. When the wire rope exceeds 4 strands, there should be a center strand. In order to prevent the wire rope from loosening after being stressed, the wire rope rotation direction should be opposite to that of the spring.

(15) Clamp springs are often used for fastening automobile liquid storage tanks, etc., and belong to the category of double torsion springs. This kind of spring can be rolled by a numerical control spring coiling machine in enterprises with conditions. Generally, enterprises can roll it by hand, and some special auxiliary tools can be made when rolling. First cut and straighten the disk material, then make it into a “U” shape, and roll it into a curved shape on a special auxiliary device. The auxiliary device can be used with the spring coiling machine fed by the sector gear, and the reciprocating mechanism of the spring coiling machine is used. The auxiliary device “b” is installed in the position of the feeding guide wheel to realize the semi-automatic production of the bending of the clamp spring, which can increase the production efficiency by about 10 times compared with manual operation.