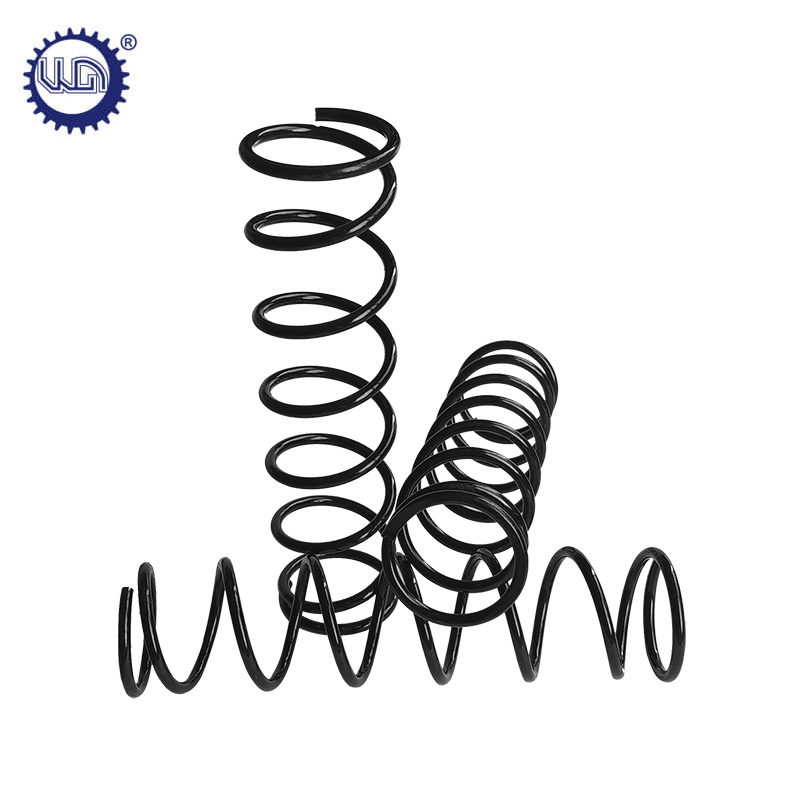

Factory customized electrophoresis compression spring

We have rich experience in customizing compression springs, torsion springs, tension springs, special-shaped springs and micro springs.

Good at designing stable mass production programs, good at solving process problems, mass production problems. The company has dozens of sets of equipment, more than ten years of production experience.

Description

Feature

1. Control the movement of machinery, such as the valve spring in the internal combustion engine, the control spring in the clutch, etc.

2. Absorb vibration and impact energy, such as the buffer spring under the car, train carriage, vibration absorbing spring in the coupling.

3. Store and output energy as power, such as clock spring, gun spring, etc.

4. Used as force measuring element, such as force measuring device, spring in scale, etc. The load and deformation of the spring is called the spring stiffness, the greater the stiffness, the harder the spring.

Material

1. Carbon steel and alloy steel springs mainly add silicon, manganese, chromium, vanadium, molybdenum and other metal elements to the steel wire to increase the elasticity and fatigue limit of the spring and make it impact resistant.

2. Stainless steel springs are mainly made of various types of stainless steel and are mainly used in places prone to corrosion and high temperature.

3. Copper alloy springs are mainly made of brass, phosphor copper, beryllium copper, etc. They are less elastic than steel, but have strong corrosion resistance. They are generally used in chemical machine springs, and can be used in electrical and food industries due to non-magnetic relationship.